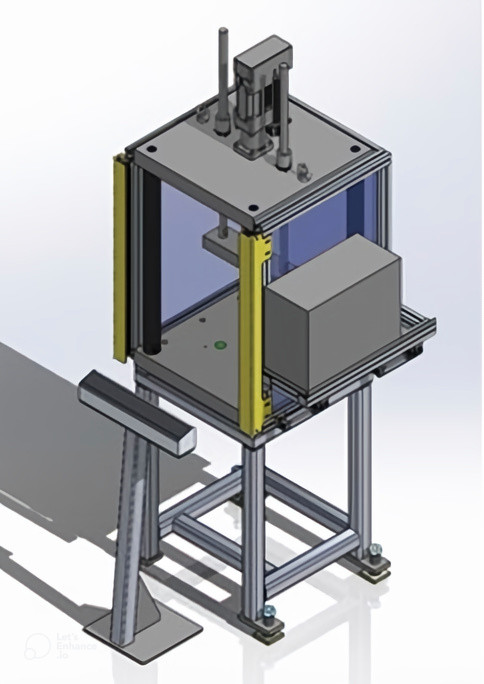

Turn-key Servo Press Stations

Customizable for Your Application!

Complete Press Solutions using CORETEC Servo Presses

Applications Include:

- Insertion of Bushings, Plugs, Snap Ring, Pins, Seals, Valve Seat and Guide

- Forming of Powders, Bushings and Rivets

- Terminal and Sheet Metal Bending

- Swaging, Bending and Throtlling of Pipes

- Punching, Staking, Die Cutting and Retaining

- Ultrasonic, Friction and Heat Welding

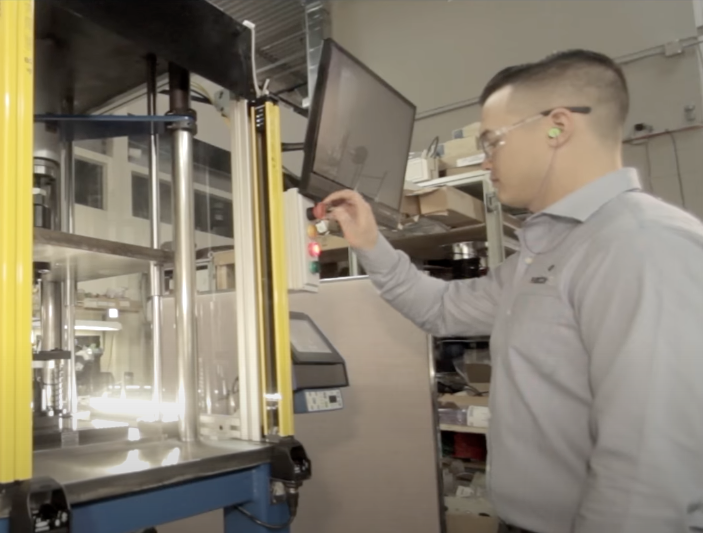

Servo Presses are becoming more common for press applications because of their superior force and position control, fast speeds & low energy consumption (almost 1/5th of a hydraulic press).

The CORETEC Multipress features are customizable to meet your application demands and feature the best value Servo Press on the market, with an embedded load cell for force feedback, simple programming and comprehensive signature analysis.

What's included with a CORETEC Multipress?

Designed to Fit Your Application

- Increase Production and Improve Quality Control

- Full Safety Compliance with Light Curtains, Tie Downs, etc.

- Full Touchscreen HMI with Customizable Screens

- Barcode and QR Code Scanners for Full Traceability

- Custom Sequencing for Multiple Operations

- Flexibly Designed for Up to 99 Part Types

Press Ranges for All Applications

- Force Ranges from 2 to 100 kN (4,500 to 22,500 lbs)

- Stroke Ranges up to 400 mm (12 inches)

- Speeds Up to 320 mm/s (12.6 inch/s)

- Load Control with a Repeatability of 0.5%

- Position Control with a Repeatability of 10 um (0.00039 inch)

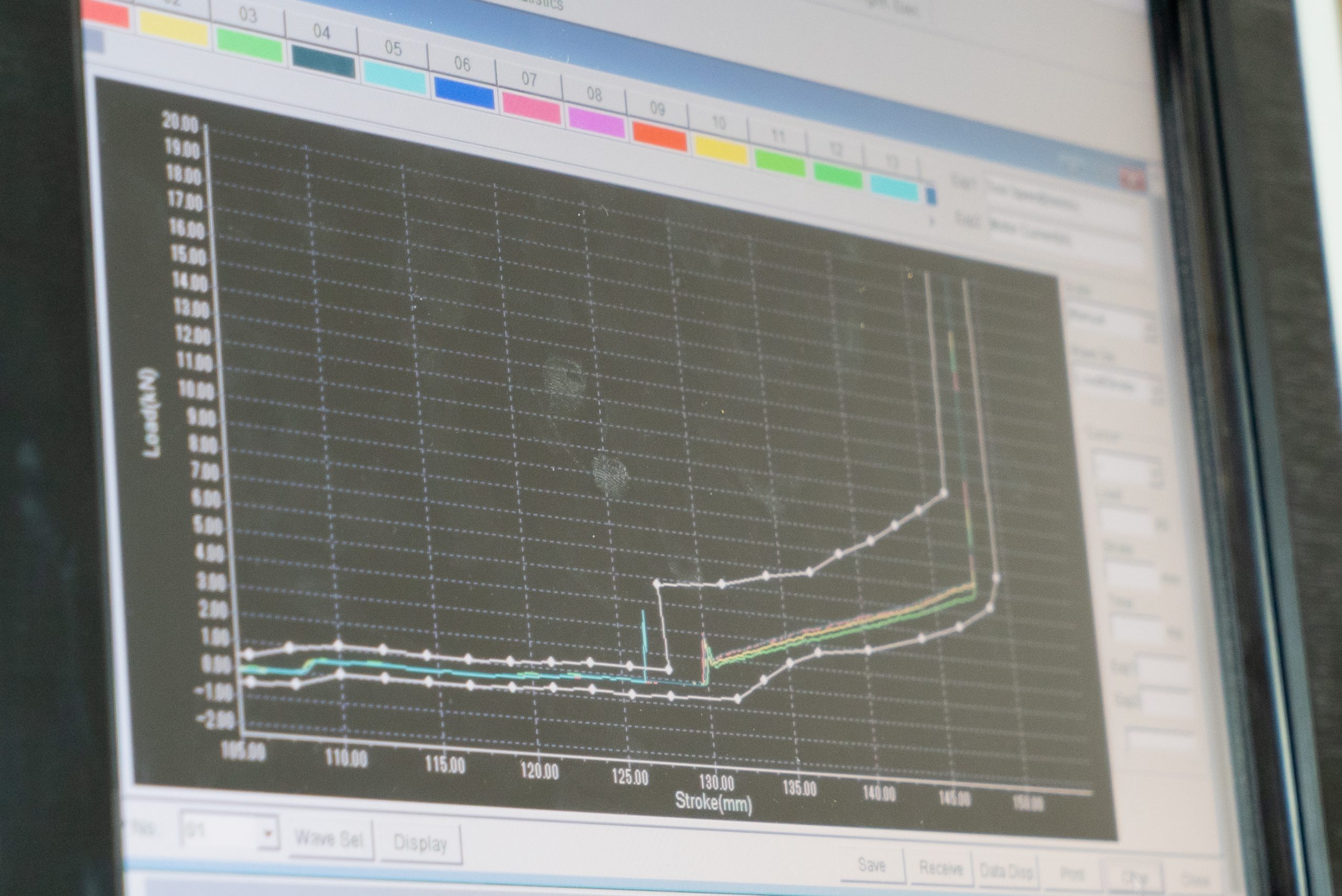

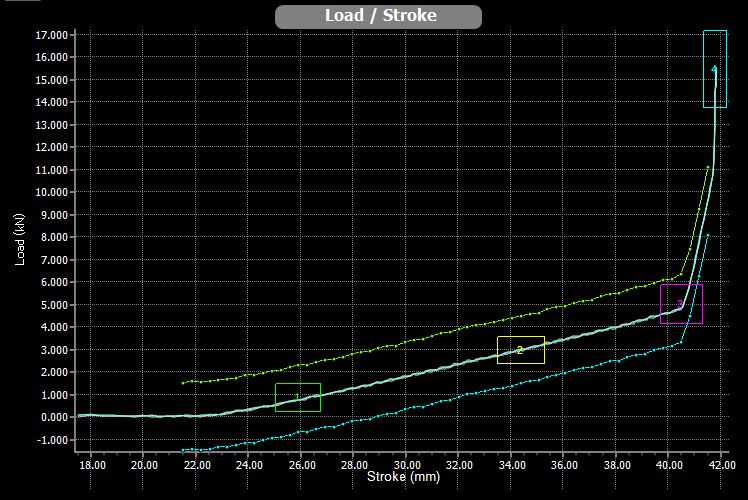

Built-in Signature Analysis

- 100% Inspection and Quality Evaluation

- Numerical Limits for Force, Displacement & Speed

- Up to 32 Envelopes

- Up to 4 Windows for Entry/Exits

- Collect Part & Serial Numbers

- Automatically Save all Data

A Complete Solution with Simple Programming, Superior Control, Signature Analysis, Data Storage & Safety Compliance.

Unbeatable Precision, Value and Price

At A-Tech Instruments, we integrate the latest technological advancements to deliver not just a press, but a promise of quality, affordability, and precision. Each press stand is custom-designed to meet the unique needs of your manufacturing processes, ensuring a perfect fit for your requirements.

How can A-Tech deliver so much value in a Press Stand?

Our secret lies in our commitment to innovation and efficiency. The CORETEC Servo Presses are designed with a focus on reducing operational costs while maximizing performance. We optimize every aspect from design to delivery, ensuring you get superior quality without the premium price tag. Our efficient production processes and strategic sourcing allow us to pass savings directly to you, making our presses the best investment for your manufacturing needs.

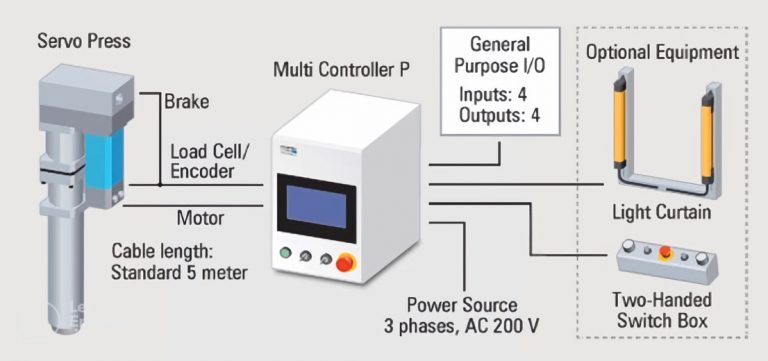

The Power is in the Coretec Multicontroller P

The Coretec Multicontroller P epitomizes innovation in servo press control, packing a comprehensive range of features into a compact, user-friendly device. This advanced controller streamlines setup by connecting directly to a power source and your servo press, readying it for immediate operation. Designed for versatility, it integrates seamlessly with any Coretec Servo Press, ensuring flexibility across various manufacturing applications.

Key Features of the Multicontroller P

- Flexibility to Integrate with any Coretec Servo Press

- Servo Controller, Fully Featured HMI, PLC, and Safety PLC

- Expandable I/O and Communication for Additional Automation

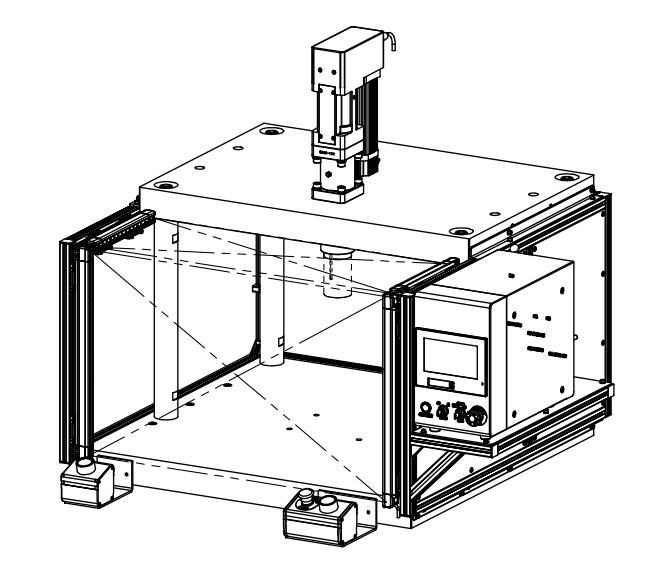

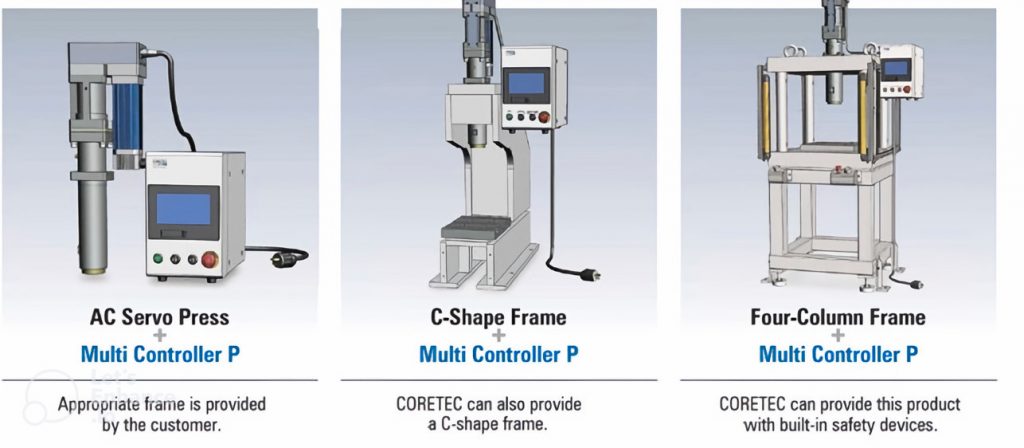

System Configuration

The versatility of the Multicontroller P extends to its ability to pair effectively with different types of CORETEC AC servo presses. Whether it’s a C-Shape Frame, a Four-Column Frame, or other custom setups, the Multicontroller P can be integrated to enhance functionality and performance.

Proudly Assembling Parts for the Following Companies: