Pneumatic Assembly Press with Force Monitoring

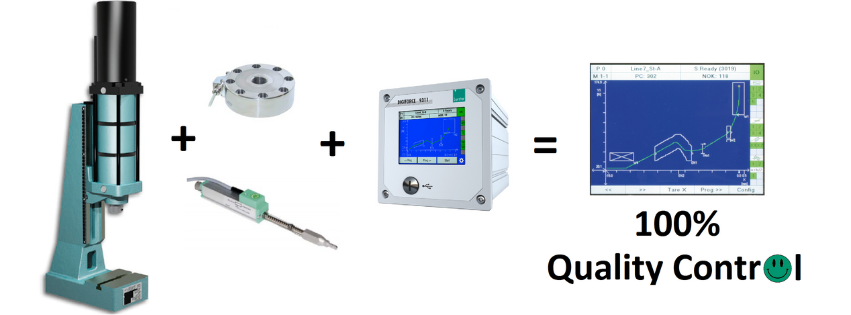

Achieve 100% Quality with the Best Value Solution!

*Fill Out the Form to Get a Free Demo and an Expert Consultation on your Application

INFO REQUEST FORM

Precision and Control in Every Press!

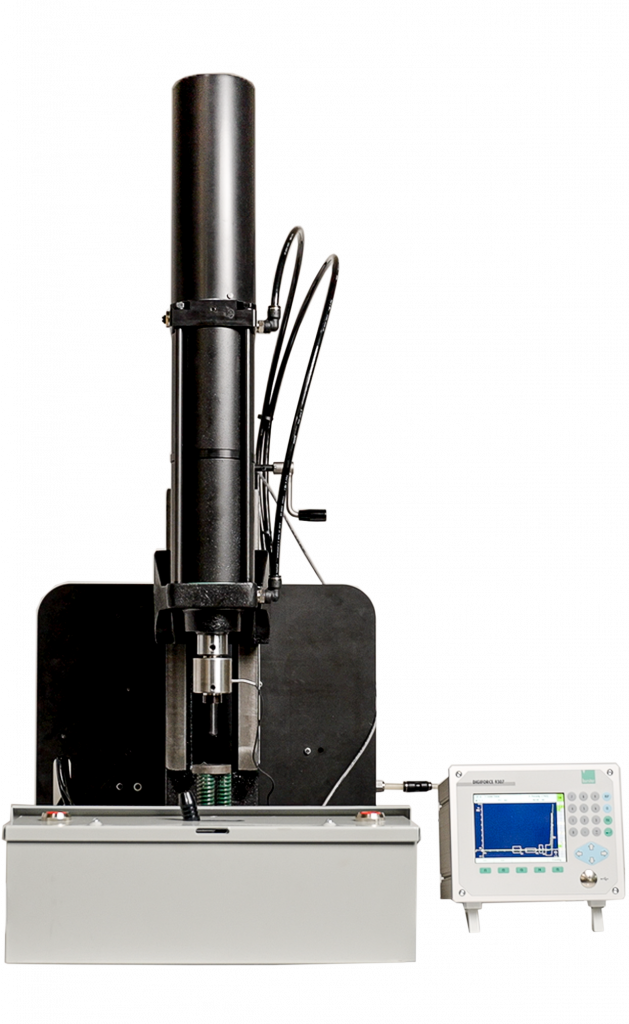

At A-Tech, we offer all-in-one pneumatic assembly press solution designed for precision, durability, and 100% quality control. Our Mader Pneumatic Presses, engineered with renowned German precision, integrate seamlessly with the Burster Digiforce monitoring system to deliver a fully pneumatic solution that eliminates the need for a PLC. This setup ensures each cycle is accurate, reliable, and repeatable; providing consistent performance you can count on.

Our presses are designed to meet the demands of industries like automotive, aerospace, electronics, and medical, offering consistent performance that scales with your needs.

With A-Tech, you’re choosing a solution with the flexibility to grow alongside your production, backed by industry-leading quality and customization options tailored to your unique needs.

Eliminate Manual Inspection Stages after Products are Assembled

Provide Complete Traceability with Comprehensive Data Collection

Key Features

- German Precision for Consistent Quality

- Force Range up to 60 kN

- Adjustable Stroke Lengths up to 120 mm

- Accuracy of up to 0.01 mm

- Modular Design for Easy Customization

- Direct-Acting System for Consistent Force Across Stroke

- Two-Hand Safety Controls – all you need to do is add tooling

- Anti-Twist Ram for Stable, Reliable Performance

- Minimal Maintenance with Pre-Greased, Oil-Free Operation

- Double-Acting Cylinders for Smooth and Powerful Action

Featuring DIGIFORCE® Press Force Signature Analysis

- Affordable Performance that is Best in Class

- 1000's of Installations in North America

- Sampling Rates up to 10 kHz

- Flexible Tigger Methods to Ensure you don't miss a cycle

- Up to 128 Measurement Programs with Unique Profiles

- Measurement Accuracy of < 0.2% of F.S.

- Complete Signature Analysis in 15 ms

- Mathematical Functions for More Challenging Applications

- Communicates with all Common PLC Interfaces

- Application & PLC Support North America

- In Stock and Ready for Quick Delivery

A Complete Solution with Real-Time Monitoring, Consistent Force Application, and Effortless Quality Assurance.

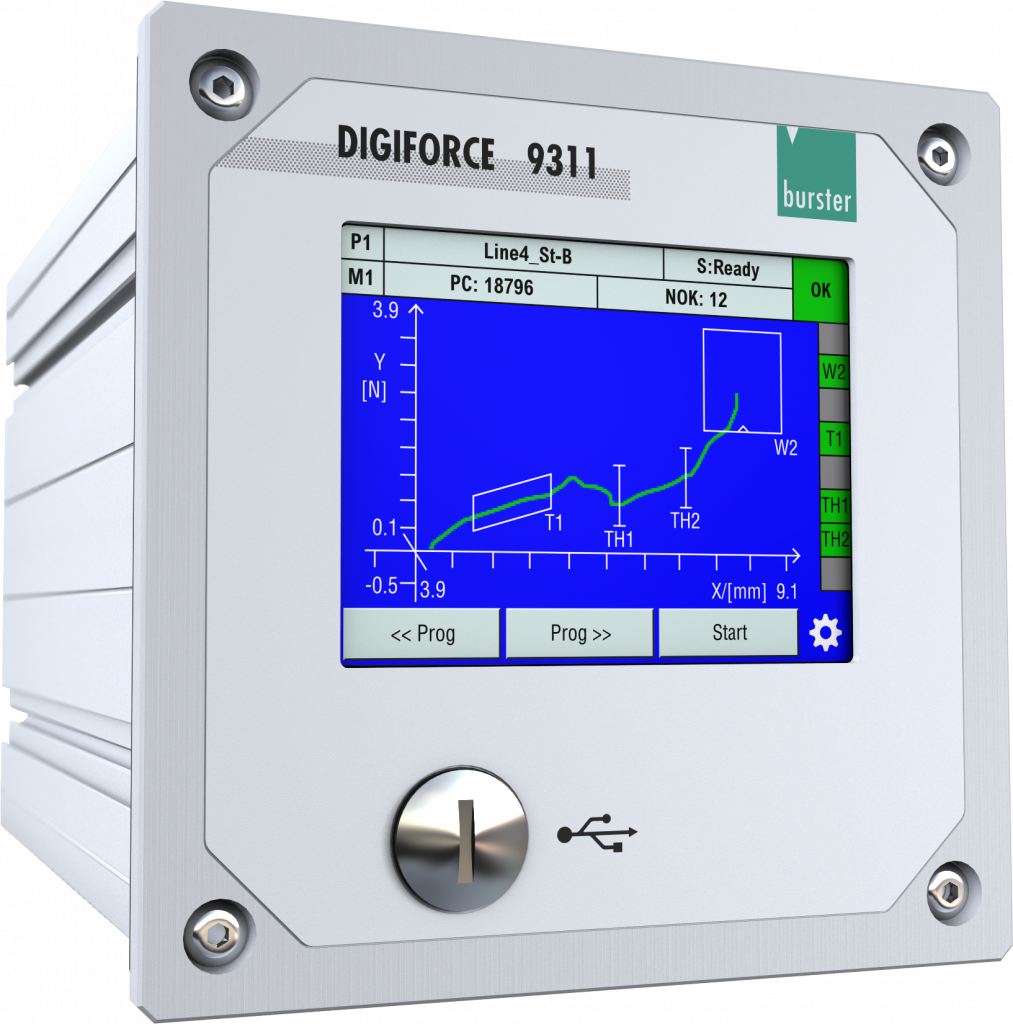

Practical Evaluation Tools

Window with configurable entry/exit sides, online signal, entry/exit coordinates, min/max values

Threshold type X or Y, configurable crossing

Trapezoid window type X or Y, configurable entry/exit sides

Envelope curve, configurable entry/exit sides

DIGIFORCE® 9311 supports numerous measurement procedures and evaluation techniques. Evaluation elements such as windows, thresholds, trapezoids, and envelopes can be used to monitor a full curve, measure process-relevant variables, and quickly signal a pass/fail result.

Why A-Tech’s Pneumatic Press is the Right Choice?

With A-Tech, you get more than just a press. Our DIGIFORCE®-integrated pneumatic press systems are designed to catch every detail, ensuring only quality products leave your production floor. You’ll gain full control over each pressing cycle, avoid costly rework, and track every step with real-time data. Plus, our flexible setup options and built-in safety features let you get started quickly and scale as your needs grow—making it a smart investment for manufacturers who prioritize precision, reliability, and efficiency.

ESTABLISHED SUCCESS WITH MANY APPLICATIONS

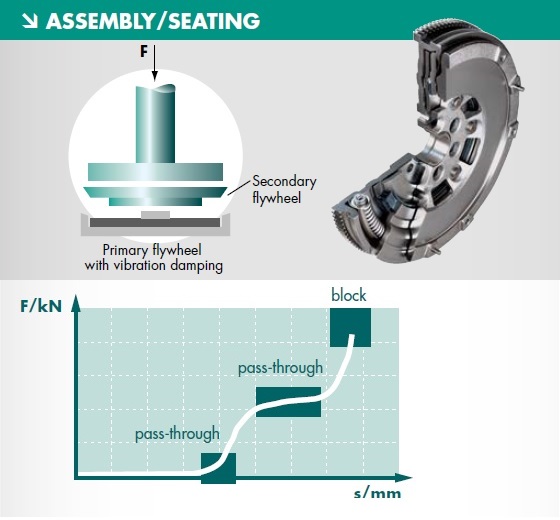

Assembly / Seating

Monitoring the assembly and seating of primary and secondary flywheels with vibration damping.

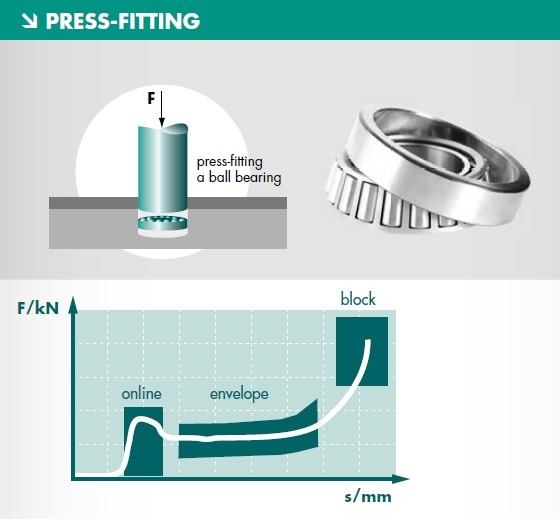

Press-Fitting

Monitoring force and position during ball bearing press-fitting to ensure proper seating.

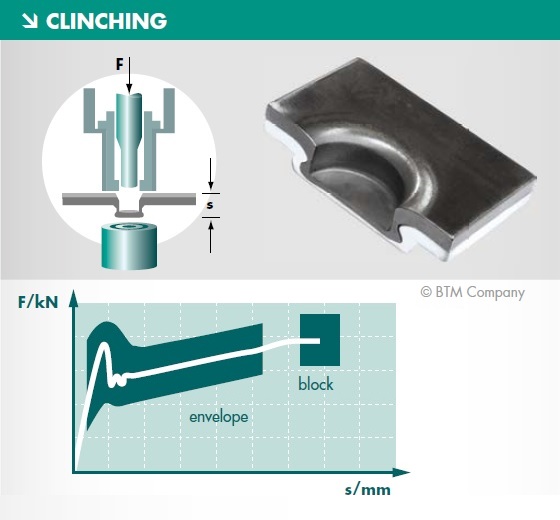

Clinching Operations

Force monitoring during clinching to join sheet metals without additional fasteners.

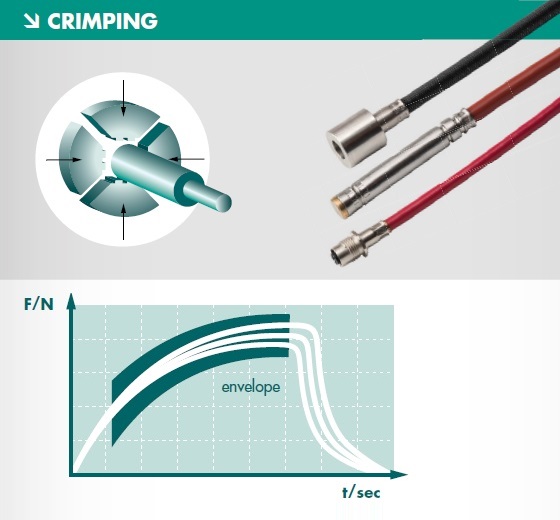

Crimping Monitoring

Force and deformation analysis during crimping to detect wear or jaw segment breakage.

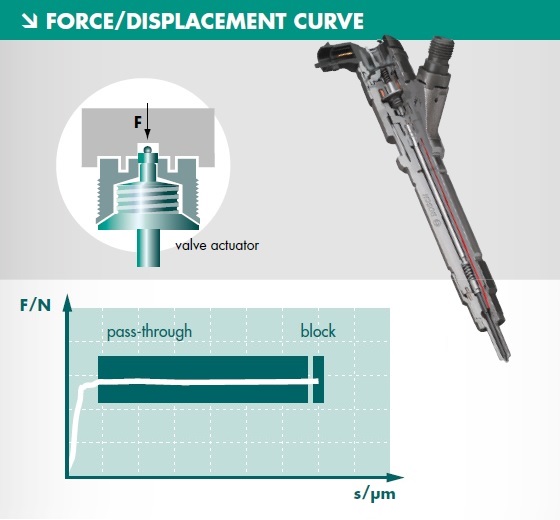

Force/Displacement Curve

Monitoring valve actuator press-insertion using force/displacement curves.

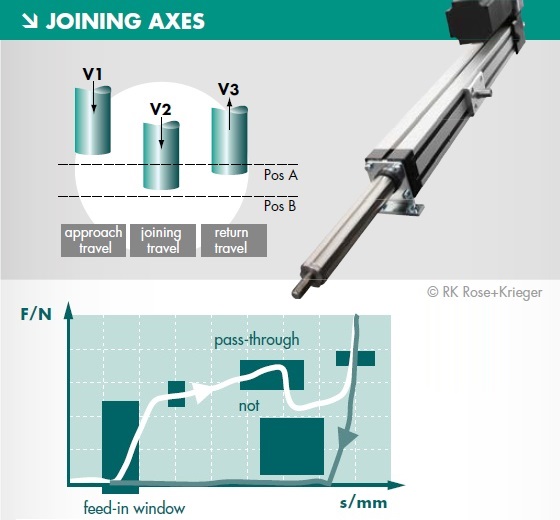

Joining Axes

Monitoring process variables during servo-electric joining operations.

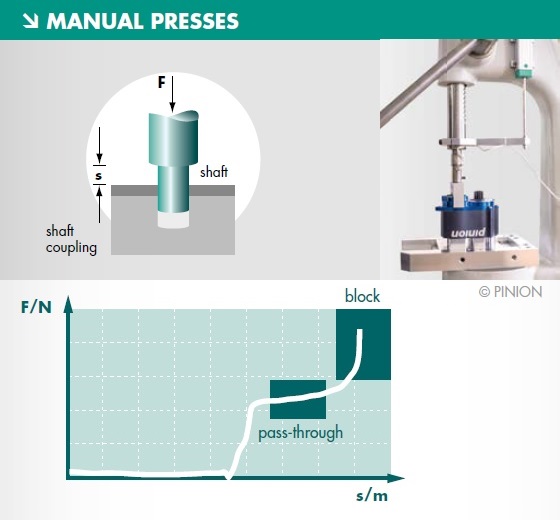

Manual Presses

Force monitoring during shaft coupling for gear assembly at manual workstations.

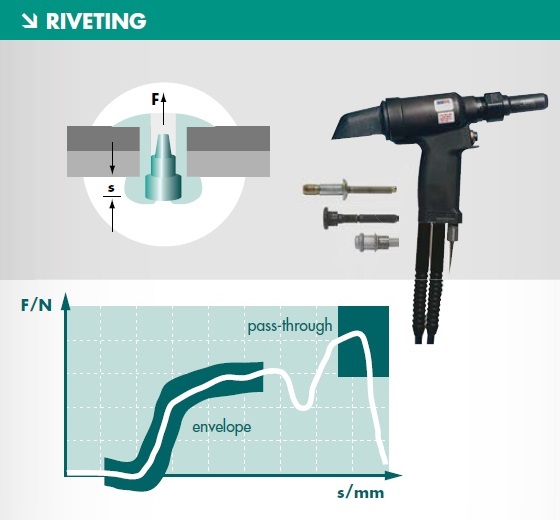

Riveting Process

Monitoring oil pressure and flow rate during riveting of ABS components

Fill Out the Form Below To...

Download Catalog

Download the Digiforce Press Force Monitoring and Mader Pneumatic Press brochures to dive deeper into model ranges, applications, product features, and industry-leading innovations.

Free Expert Consultation

Our experts will perform a free assessment of your application and provide recommendations for the most suitable press solution tailored to your needs.

Free Demo

Get a free demo of our press force monitoring and pneumatic press solutions to see how they can improve your application.

Proudly Making & Testing Parts for the Following Companies: